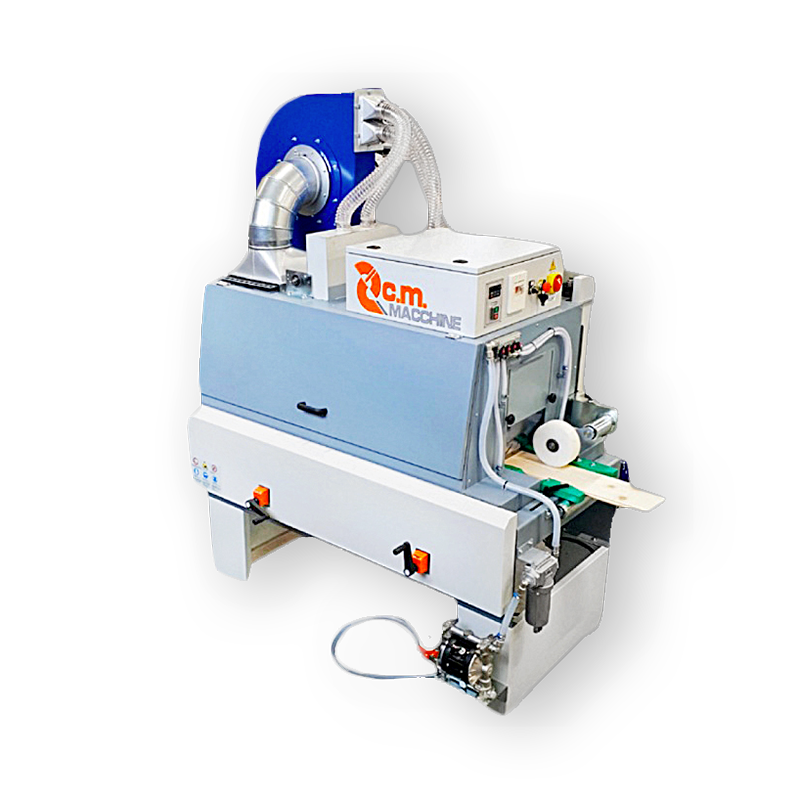

CM MACCHINE

IMPREGNATING MACHINE - PAINTING MACHINE

-TIN 200 AIR MODEL -

CM Macchine's wood painting machine TIN 200 AIR model allows you to impregnate planks, beams, lamellar beams, matchboarding and other elements for prefabricated houses, and any other type of small and medium-sized wooden element.

CM Macchine's impregnating machines, using the special nozzles, spray wood impregnating varnish on all four sides of the wooden element, returning a homogeneous and already dry product.

The TIN 200 AIR model allows the use of both water-based and solvent-based paints.

The impregnating machine is widely customizable upon customer request and can be completely Teflon-coated.

TIN EVO AIR 200 - ENG

Send download link to:

TIN 200 AIR

MODEL COMPOSITION

The TIN 200 AIR model Impregnating machine for beams and matchboarding consists of:

MACHINE STRUCTURE

The TIN 200 AIR Impregnating machine is made up of 4 air vents on 4 sides (1 per side).

THE PHASES IN DETAIL

WORKING PROCESS

The working process of the TIN 200 AIR Impregnating machine for beams and matchboarding consists of four phases:

1. The workpiece is introduced into the Impregnating machine and Towed by the feeding rollers into the spray chamber

2. The nozzles spray the paint on the four sides of the wooden element

3. The piece advances until it reaches the motorized blowers, which eliminate the excess paint and dry the wooden element.

4. The workpiece thus worked comes out of the machine sliding on an exit roller conveyor.

Dati Tecnici | ||

Maximum workpiece height | mm | 220 |

Maximum workpiece width | mm | 200 |

Minimum workpiece length | mm | 800 |

Electronically variable feed speed | m/min | from 0 to 45 |

Machine length | mm | 1950 |

Machine width | mm | 1250 |

Machine height | mm | 2300 |

Total machine weight | kg | 700 |

CM MACCHINE