CM MACCHINE

HYDRAULIC CLAMPS FOR LAMELLAR BEAMS

-MODEL STP6 and STP12-

The CM Macchine hydraulic clamp has been designed for coupling several boards by gluing to form a single homogeneous beam.

Two distinct models of hydraulic clamps for laminated beams are available, based on the work capacity served.

STP6 e STP12 - ENG

Send download link to:

STP6 and STP12 MODEL COMPOSITION

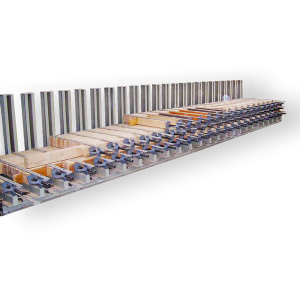

MACHINE STRUCTURE

The press was designed and built to glue overlapping wooden boards together to form a single piece.

The two models available are STP6 and STP12.

STP6:

- Working capacity mm 6.000 x 1350 x 300.

- 12 Vertical pillars with hydraulic push cylinder.

- 4 horizontal sliding pillars with pneumatic push cylinder.

STP12:

- Working capacity mm 12.000 x 1350 x 300.

- 12 Vertical pillars with hydraulic push cylinder.

- 8 Horizontal sliding pillars with pneumatic push cylinder.

MOBILE WORKTABLE

A mobile platform that allows you to overturn, load and unload both the boards and the beam. It also brings the pack of boards from a horizontal position to a vertical one to be pressed.

FIXED FLOOR

The press consists of a fixed structure with a horizontal support surface and a vertical abutment wall.

THE PHASES IN DETAIL

WORKING PROCESS

The manufacturing process of the hydraulic clamp for laminated beams consists of four phases:

1. Manually place the boards with glue on the folding table.

2. Once the package has been prepared, it is overturned inside the press. At this point the mobile part hooks to the main structure.

3. The lateral pressers bring the boards close to the wall, aligning them and the upper pressers compress the package.

4. At the end of the process, remove the boards from the press.

CM MACCHINE