CM MACCHINE

4 SIDES PLANER

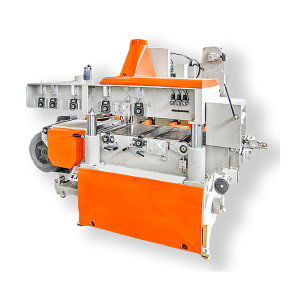

-KOMPAT RUSTIFLEX MODEL-

The 4-sides planer model KOMPAT RUSTIFLEX is a highly powerful and solid machine equipped with a cardan transmission and 4 or 6 lifting columns.

It is placed at the intermediate level of the range of CM Macchine planers with maximum working dimensions of 300 mm in height and 1000 mm in width.

Rustiflex corner units allow you to choose the type of corner you want to create. Equipped with removable tracers, they allow you to copy an existing edge, while thanks to the shaped cams, they allow you to create irregular (rustic) edges.

Designed by Cm Macchine for planing wood in the form of boards, matchboards, floors and other elements for prefabricated houses, KOMPAT RUSTIFLEX can be widely customized in configuration according to customer needs.

It can be equipped with a multi-blade shaft and additional, even universal, shafts.

KOMPAT RUSTIFLEX - ENG

Send download link to:

KOMPAT RUSTIFLEX

MODEL COMPOSITION

>

MACHINE STRUCTURE

Made of heavy electro-welded mechanical carpentry characterized by high resistance and stability.

MOBILE WORK SURFACE

Removal surface with surface planer sliding on dovetail guides.

FIXED WORKTABLE

Equipped with 4 chromed columns with 4 high precision reducers and movable upper part.

TOWING ROLLERS

Towed by cardan shaft.

VERTICAL OPPOSED SHAFTS

Shafts positioned vertically opposite to each other.

MOTORIZED EXTRACTOR

Fully motorized extractor

RUSTIFLEX CHAMFERING GROUPS

With 4 motors inclined at 45°, each mounted on an edge and equipped with an independent movement of 60 mm.

Minimum workable dimensions: beam 60 x 60 mm

Power each. motor: 7.5 Kw

Two different edge processing possibilities:

1) With a constant profile, even with a large diameter

2) Copying or cleaning an existing rustic edge, like “Uso Fiume” up to 150 mm radius edge diam. 120mm

THE PHASES IN DETAIL

WORKING PROCESS

The working process of the KOMPAT RUSTIFLEX wood planer consists of three stages:

1. The workpiece is inserted into the planer and pulled in by the feeding rollers.

2. Rustiflex edge trimming units copy an existing edge with the removable tracers or create an irregular (rustic) edge with the shaped cams.

3. The workpiece thus worked comes out of the machine sliding on an exit roller conveyor.

Technical data | ||

Minimum working width | mm | 50 |

Minimum working width with chamferings | mm | 80 |

Maximum working width | mm | 1000 |

Minimum working height | mm | 20 |

Minimum working height (on request) | mm | 15 |

Maximum working height | mm | 300 |

Electronically variable feed speed | m/min | from 6 to 30 |

Maximum removal | mm | 10 |

Maximum removal with enhanced motors | mm | 15 |

CM MACCHINE