CM MACCHINE

4-SIDES SANDING MACHINE

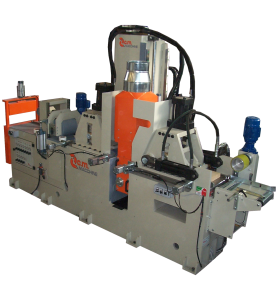

- SAND 600 4S MODEL -

The CM Macchine SAND 600 4S 4-sides sanding machine with chamfering units allows you to sand beams, roofing elements and wooden structures.

Professional wood sander, it is equipped with 4 sanding units, one on each side, which allow for rapid and efficient processing of the material and 45° chamfering units with copying cutter.

The convenient control panel with Touch Screen programmer ensures optimal management of both the functions and the pressure regulators of the operating units.

SAND 600 4S - ENG

Send download link to:

SAND 600 4S

MODEL COMPOSITION

The SAND 600 4S- 4-sided sanding machine for wood is composed of:

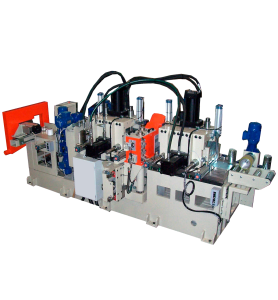

MACHINE STRUCTURE

The structure is in electro-welded mechanical carpentry with high resistance and stability. This guarantees the sanding machine high torsional rigidity and maximum precision in any process.

PIECES FEEDING ROLLERS

Rollers characterized by a large diameter, to ensure maximum traction even with heavy beams.

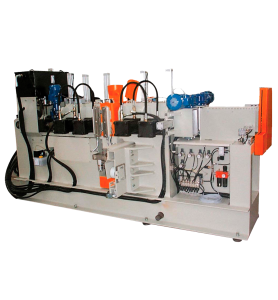

FLOATING SANDING UNITS

1 group per side of the pad type for beams, with 1900 mm belt development and high power fixed speed motor. The machine is equipped with a patented interchangeable pad and is characterized by the oscillation of the sanding belts.

CHAMFERING GROUPS

The groups are at 45° and equipped with cutter with copier.

ELECTRICAL CABINET

This element is integral with the machine structure. All components are first choice supplied by international companies in order to offer easy availability on the market.

CONTROL PANEL

The control panel is equipped with a Touch Screen programmer for managing all the machine functions and the pressure regulators of the operating units.

THE PHASES IN DETAIL

WORKING PROCESS

The working process of the SAND 600 4S - 2-sided sanding machine consists of three stages:

1. The workpiece is placed on a roller conveyor and inserted under the press, inside the machine

2. The piece is transported by rubber rollers into the brushing area and worked by the sanding units.

3. The workpiece thus worked comes out of the machine sliding on an exit roller conveyor.

Dati Tecnici | ||

Altezza massima pezzo lavorabile | mm | 600 |

Larghezza massima pezzo lavorabile | mm | 600 |

Lunghezza minima pezzo lavorabile | mm | 1000 |

Altezza piano di lavoro | m/m | 900 |

Lunghezza macchina | mm | 2000 |

Larghezza macchina | mm | 2400 |

Altezza macchina | mm | 2150 |

Peso totale macchina | kg | 3000 |

CM MACCHINE

Discover other products

T-LAM 50

TESTING MACHINE

Discover product

FINGER JOINT HPX-O (HORIZONTAL) 12 20 30 40 TONS

Discover product

FINGER JOINT HPX-V (VERTICAL) 12 20 30 40 TONS

Discover product

FINGER JOINT HPX-OV (HORIZONTAL AND VERTICAL) 12 20 30 40 TONS

Discover product