CM MACCHINE

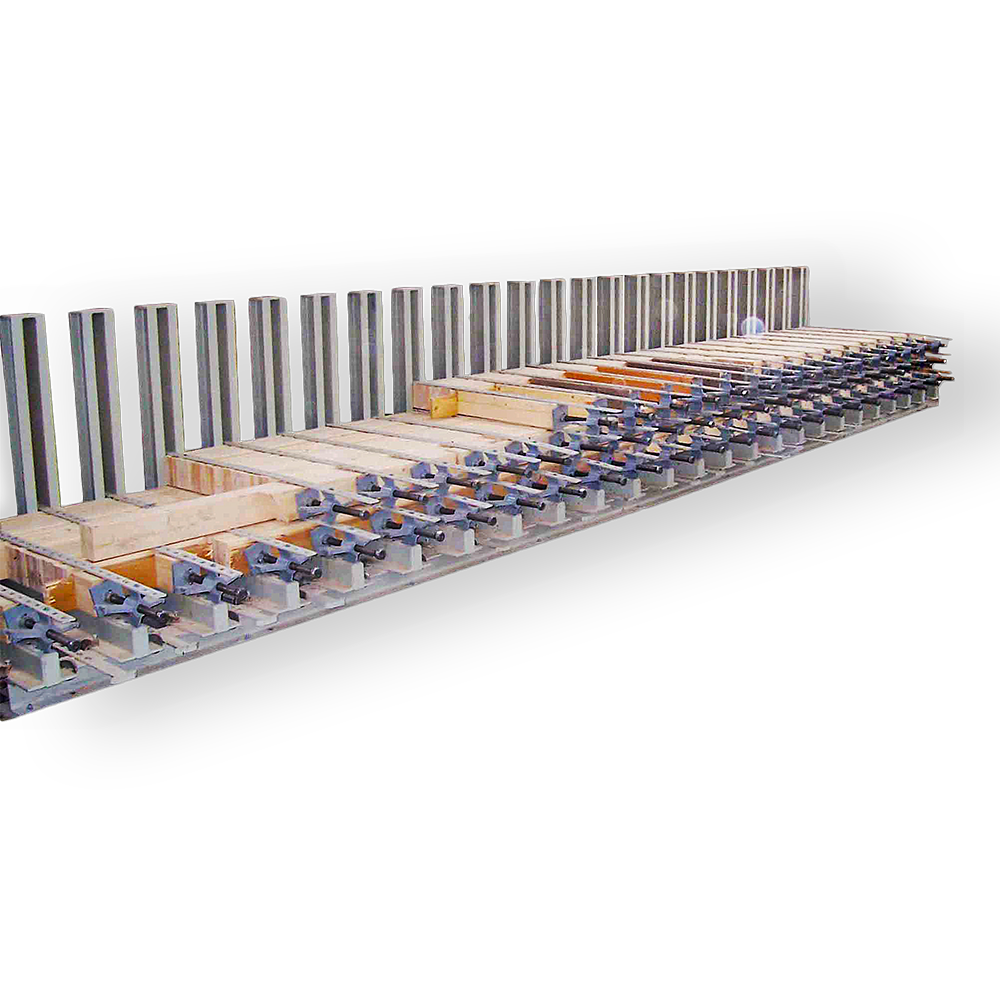

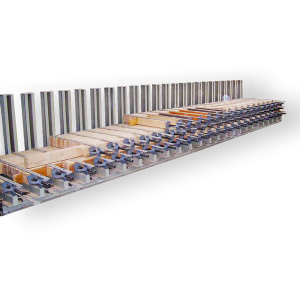

MECHANICAL CLAMP WITH ELEMENTS BEAM PRESS

- STR-M MODEL -

The CM Macchine mechanical press was designed to glue overlapping wooden boards together, to form a single body. It is possible to work both straight and curved.

The function of the mechanical clamp is to press. So it joints semi-finished lamellas, previously spread with glue, on the wide side, to obtain both curved and straight laminated beams, depending on the case.

BEAM PRESS - ENG

Send download link to:

MODEL COMPOSITION STR-M

MACHINE STRUCTURE

The press consists of basic elements and mobile mechanical brackets of robust construction.

The structure, created with elements of high thickness, is modular with the possibility of extension in length and has a center distance between elements of 40 mm, in accordance with the provisions of DIN standards.

Each meter is made up of 2.5 draft elements per meter at 40 cm. Each draft element has a useful lamella loading base of 1.45 m and is equipped with:

- jack anchor brackets

- draft jacks to form 4 beam formation levels, for a total of 5.8 meters of useful draft width.

The draft elements can be moved on two or more rails placed below and form the basis of the whole clamp in order to be able to tighten even curved beams.

OTHER ELEMENTS

- • Pneumatic screwdriver to quickly tighten the jacks.

- Torque wrench.

THE PHASES IN DETAIL

WORKING PROCESS

The manufacturing process of the mechanical beam press with elements Beam Press consists of three phases:

1. Place the glued lamella on the clamp, fix them and check the tightness.

2. Leave the glue to act for the necessary time (data provided by the glue supplier).

3. Once the glue has dried, the beam can be removed from the press.

CM MACCHINE